Upgrades

Draining Channels Upgrade

Replacement of existing draining systems with high drain surface channels.

- Shorter pressing times

- Increased filling capacity

- Fewer solids

- Easier cleaning

Slotting Evolution In Diemme Enologia’s Channels

- Starting evolution

- Slot 30×1.8mm

- Pitch 60x20mm (not aligned)

- N°125 slot/linear meter

- Slotted surface: 67.5 cm²/m

- First evolution

- Slot 30×1.8mm

- Pitch 38x20mm (not aligned)

- N°200 slot/linear meter

- Slotted surface: 108 cm²/m

- Increase in 1): +60%

- Current features

- Slot 30×1.8mm

- Pitch 38x10mm (not aligned)

- N°400 slot/linear meter

- Slotted surface: 216 cm²/m

- Increase in 1): +220%

- Increase in 2): +100%

Repositioning of pomace conveyors under the pressing membrane

Better sanitation, shorter wash and discharge times

- Quicker pomace removal

- Decrease in residual pomace inside the press

- Easier cleaning of the pressing tank

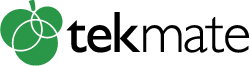

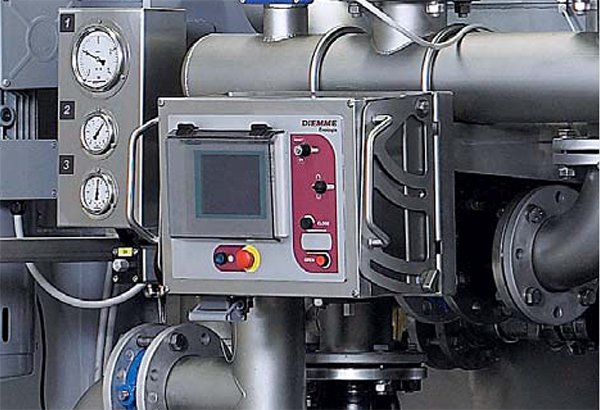

Electric cabinet and HMI update

Adjustable HMI that can be removed for winter storage

- Large number and increased flexibility of the pressing programs

- Remote display of the door location with customized positions

- Simple and user-friendly programming data processing in tree view

Replacement of obsolete or discontinued control systems

Electric cabinet replacement for Diemme Enologia machines and other brands with a new stainless steel panel

- Updated components

- Increase in reliability

- Adaptation to comply with current regulations